BOEING Composite Lab

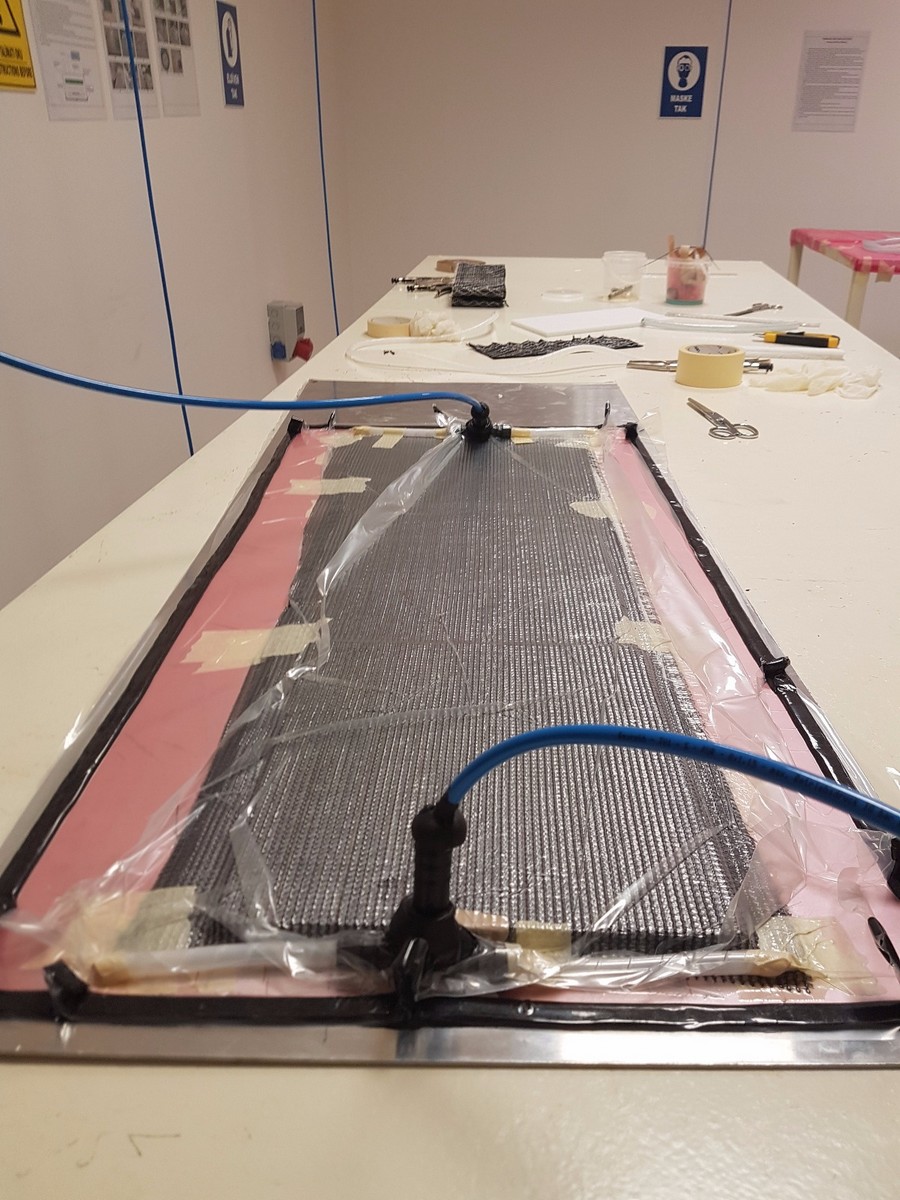

Ege University Aviation Vocational School Composite Laboratory started to be established with Boeing contributions in 2014. In our laboratory; Hot jointing, autoclave molding, hand laying, pre-preg laying and resin transfer methods are planned to provide training on composite part production and repairs. Manual depositing, resin transfer and pre-preg laying methods were created with support from the Boeing project. Work on other methods is ongoing.

In our laboratory; One cold room with a size of 8 square meters and a cooling compartment with a temperature of -18 degrees, a clean room with a positive pressure for the production of composite materials, vacuum lines and a furnace for curing the materials to be produced. Also NDT laboratory and Radiography laboratory are used to make the tests of the products with the Structural-Machine Atelier in the shape of composite products.